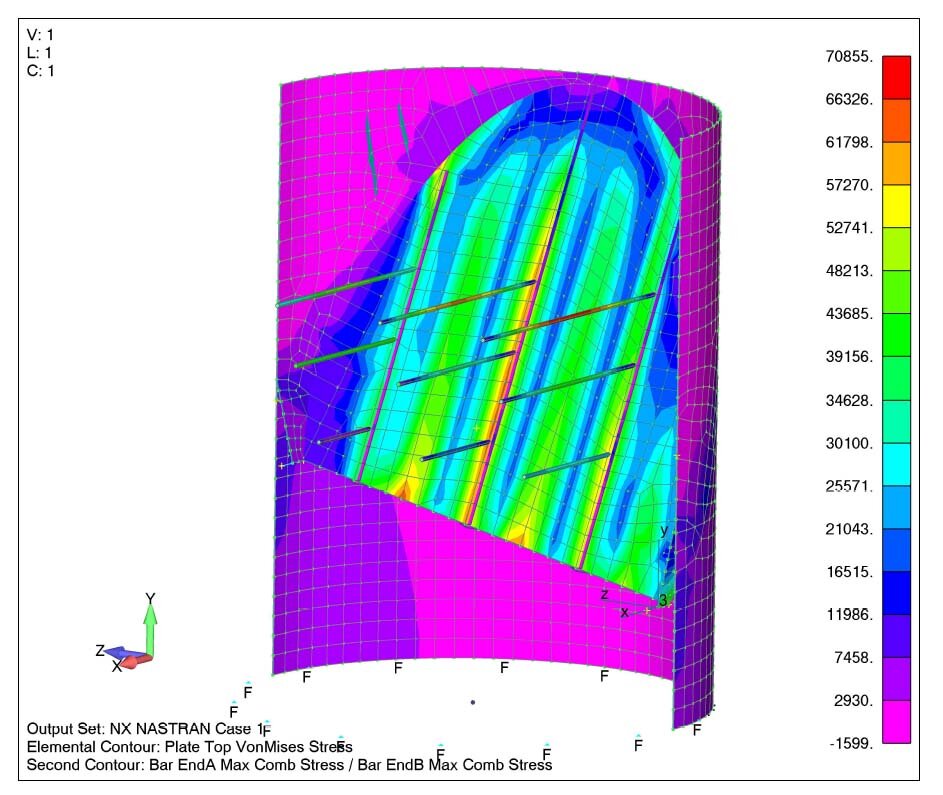

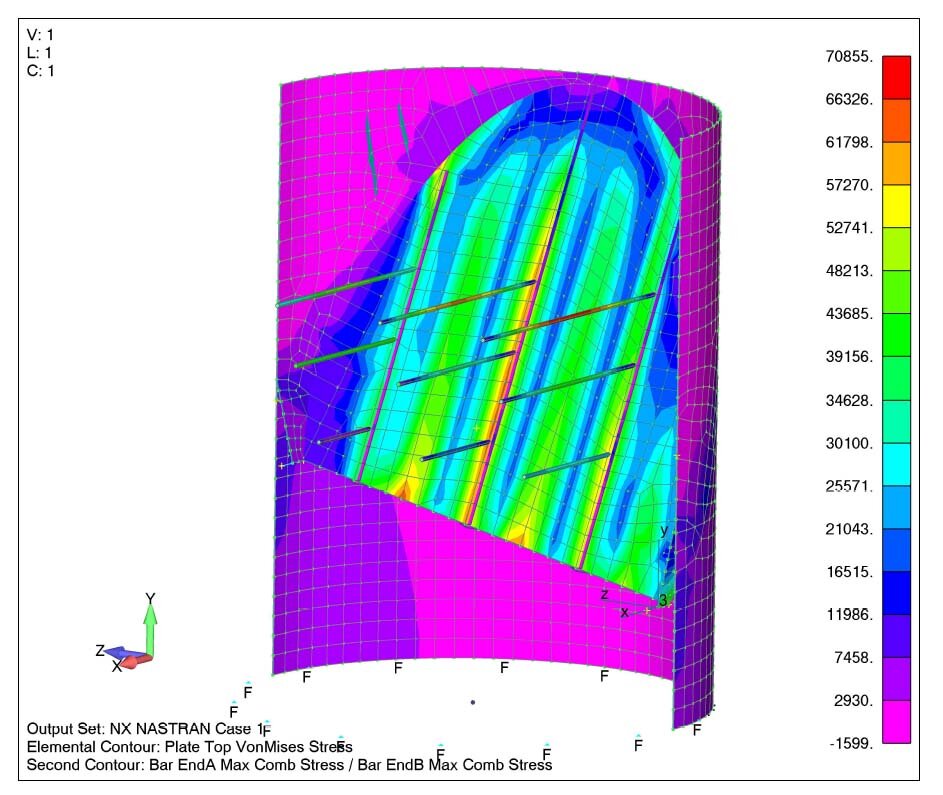

Aircraft Beam, US Army

Confirmation is peace of mind. The US Army needed reassurance that the hand analysis of a repair designed for their aircraft was correct. We developed a finite element model and were able to confirm the original hand analysis.

Rail Spur Construction, Vancouver, WA

Sometimes engineering is the easy part of a project. The challenge of this project was developing the logistical plan that convinced the plant leadership and the contractor that the rail spur could be demolished and re-laid in three days while the plant remained fully operational.

Exhaust Stack, Rosenberg, TX

The plant's insurance company asked them to provide documentation that the existing exhaust stack structure and shoring would meet current tropical storm wind loading per FM Global Data Sheet 1-28. Using finite element analysis and stack properties collected during a site survey, we were able to show that the existing stack and shoring met the current wind loading requirements.

Roof Truss Structural Analysis, Fayetteville, TN

The plant leadership team wanted to upgrade their dock loading system with new roof supported dock equipment to decrease the loadout time for their trailers. We performed a structural analysis of the existing roof trusses to ensure that the roof supported equipment did not overload the roof structure.

Silo Hopper Failure, Los Angeles, CA

The fabricator needed help determining the failure mode of strut ties in a silo hopper. Using finite element analysis and EN 1991-4, we were able to show that the struts were being overloaded by the internally stored material.

Elevated Maintenance Platform, Rancho Cucamonga, CA

The maintenance team for a distribution center needed a platform to service the upper portion of a 70ft tall robot located inside an existing rack-supported building. With only field measurements and conference calls from the fabricator, we designed a maintenance platform that attached to the existing building structure that provided the needed access 70 feet above the finished floor.

Fall Protection Analysis, Austin, TX

The fabricator needed confirmation that a fall protection anchor could be added to a fixed wall ladder without overloading the ladder components. Using finite element analysis we were able to help the fabricator determine the appropriate amount of reinforcement that would prevent ladder component failures if a fall event occurred.

Silo Emergency Shoring, Dallas, TX

The general contractor needed emergency shoring of a silo to provide additional time to resolve fit up issues with the replacement of structural panels. We were able to get on-site, assess the structural need, and develop a shoring plan within 4 hours of receiving their call.